75mm PVC Pipe Cutter

75mm PVC Pipe Cutter for Cutting PEX, PPR, PVC, Aluminum-Plastic Pipe, Ideal for Household, Maintenance, Plumber

| Item No.: | CS29575 |

| Optional Material of Blade: | SK-5 Steel, 65Mn Steel, Stainless Steel (3Cr13) |

| Material of Body: | Die-Casting Industrial Aluminum Alloy |

| Surface Finishing of Blade: | Teflon Coated |

| Surface Finishing of Body: | Spray Painted |

| Weight: | 1,230g |

| Packaging: | Blister Card, 1pcs/Inner Box, 20pcs/Carton |

| MEAS. of Carton: | 50*42*35cm | G.W./N.W. of Carton: | 29/28kgs |

| Cutting Ability: | Up to 75mm (3") Dia. |

| Application: | Suitable for Cutting PVC Pipe, CPVC Pipe, PP Pipe, PEX Pipe, PE Pipe, Single-Layer Tubing |

Detailed Description:

Extra Large 3" 75mm Ratcheting PVC Pipe Cutter

Selection of high-quality aluminum alloy die-casting, the surface of red plastic powder spraying, specifications 14mm to 63MM, is an ideal composite pipe cutting instrument of first choice. Screw, blades, wire teeth through a special heat treatment, the rapid advance and retreat design, the use of more efficient.75mm PVC Pipe Cutter's ratchet mechanism

High-leverage ratchet action cuts smoothly and with minimal effort. Produces fast, square cuts with no burrs to remove or mess to cleaning up.

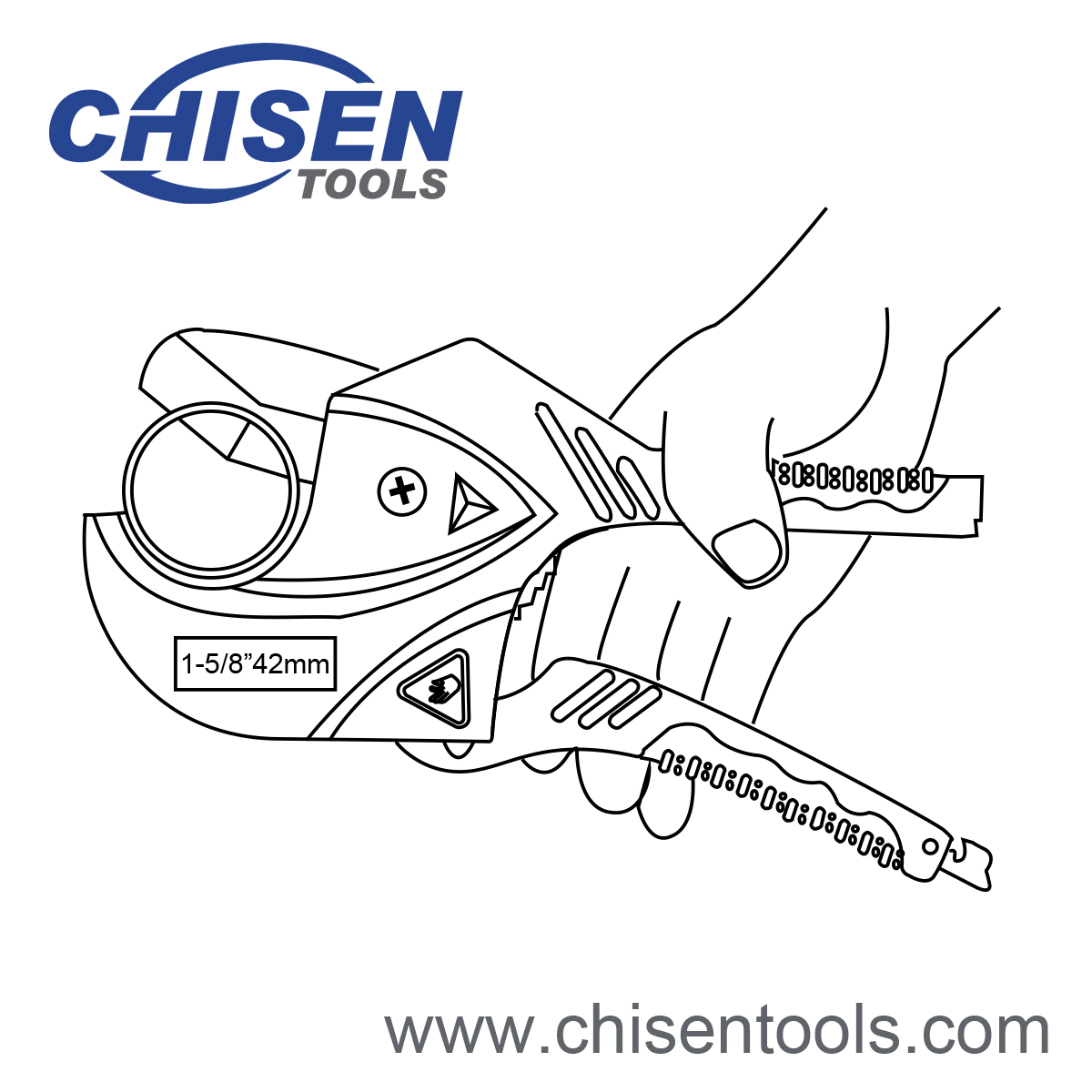

How to Use Pipe Cutter

First Step:

Open the safety lock. Open the handles carefully and use the ratchet spring to open the blade.

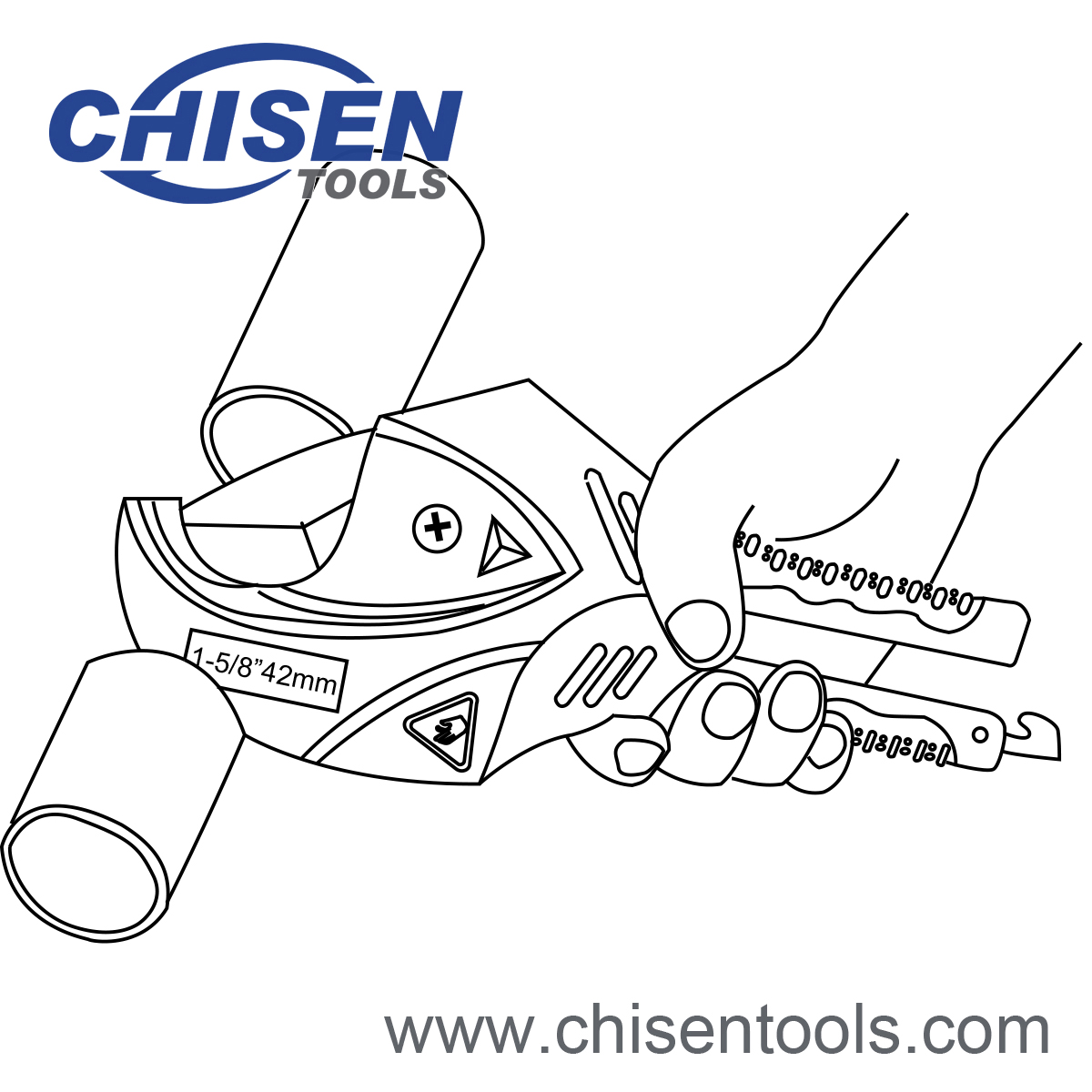

Second Step:

Insert the tube into the blade, and hold the handle and press it tightly. You can use the self-locking ratchet design to adjust the opening size of the knife.

Third Step:

Clean the blades in time after use or apply protective oil for protection. Please fasten the safety lock in time to ensure safety.

How to Choose Pipe Cutter?

What is PVC Pipe?

Polyvinyl chloride (PVC) pipe is a common material in drains, vents, water mains, and irrigation systems because it’s long lasting, lightweight, durable, and easy to recycle. However, installing PVC pipe requires cutting through the material with a PVC pipe-cutting tool. A PVC pipe cutter can come in a variety of types, ranging from a simple manual PVC pipe-cutter tool that needs tightening by hand to a fully electric PVC tube cutter that does all the work with the push of a button.Plastic pipe cutters need to cut new PVC pipe effectively to the appropriate length or cut through installed PVC pipe for modification or removal. This guide can help users learn more about the various pipe-cutter types and how to choose the best PVC pipe cutters for their next project.

What to Consider When Choosing the Best PVC Pipe Cutter?

Before selecting a new PVC cutting tool for a tool box or workshop, it’s recommended users learn more about the various types of PVC cutting tools, the cutting capacity, and blade material in order to choose the best PVC pipe cutter for their needs.Type

When it comes to types of PVC cutters, users can choose from several different options, including ratcheting, manual, spring-loaded, electric, and handsaw. Ratcheting PVC pipe cutters are great for one-handed use because of the ratcheting system. When the handles are squeezed together, the blade starts to close, ratcheting into a new position. The cutter remains in this position even when the user releases the handles, eliminating the need to worry about the blade releasing when adjusting the grip. One squeeze on the handles won’t slice through the pipe, but it gradually closes the blade around the pipe. With each subsequent squeeze, the blade begins to slice through the PVC pipe until it has cut cleanly through the material.

Ratcheting PVC pipe cutters are great for one-handed use because of the ratcheting system. When the handles are squeezed together, the blade starts to close, ratcheting into a new position. The cutter remains in this position even when the user releases the handles, eliminating the need to worry about the blade releasing when adjusting the grip. One squeeze on the handles won’t slice through the pipe, but it gradually closes the blade around the pipe. With each subsequent squeeze, the blade begins to slice through the PVC pipe until it has cut cleanly through the material. Manual PVC pipe cutters have a hook-shaped appearance with an opening that has a cutting wheel to cut through PVC pipe. Slide the pipe into the opening between the cutting wheel and the top of the hook shape. Use the adjustment knob on the handle of the cutter to tighten the grip on the pipe, and then begin moving the cutter around the pipe. If the cutter feels too loose after a few turns, turn the adjustment knob to tighten the grip and resume cutting. After several rotations around the pipe and a few adjustments to ensure the blade is sinking deeper into the pipe with each revolution, the cutter will slice completely through the pipe.

Spring-loaded PVC pipe cutters are simple to use, but they can cause significant strain on the user’s hands. This is because they are essentially a set of oversize scissors with a single blade intended for cutting through tough, durable PVC pipe. Users must rely on their own strength and the sharpness of the cutting blade to get through the PVC. However, the spring-loaded jaws can help alleviate some of this strain during use.

Electric PVC pipe cutters are the easiest to use, but they rely on a charged battery pack for power, so if the battery isn’t charged, this type of cutter is useless. With a charged electric cutter, all the user needs to do is position the pipe in the cutting jaws and squeeze the trigger. The pipe cutter will take care of the rest, slicing through the PVC pipe quickly and effectively.

Handsaws are not exclusively used for cutting PVC pipe, but they work if one of the other types isn’t available or if the pipe is too big for the pipe cutter’s jaws. Hacksaws are a type of handsaw commonly used by plumbers to cut through PVC, copper, lead, galvanized iron, and more. For those who frequently take up plumbing projects around the home, it’s recommended to invest in a handsaw.

Cutting Capacity

When looking for a new PVC pipe cutter, factor in the size of the pipe that will be cut to ensure that the cutter jaws can fit around the pipe. Unfortunately, this can get confusing because the stated diameter of a PVC pipe refers to the inner diameter instead of the outer diameter.For example, a piece of PVC pipe with a diameter of 1⅝ inch has an inner diameter that measures 1⅝ inch, so a PVC pipe cutter with a maximum cutting capacity of 1⅝ inch would not be able to fit around the pipe. The actual measurement needed to compare the cutting capacity with the pipe is the outer diameter.

The outer diameter of the pipe depends on the PVC schedule. PVC schedule refers to the thickness of the PVC pipe wall. The most common option is schedule 40, but schedule 80, schedule 120, and a smaller option known as “thin-wall PVC” also are available. Before deciding on a new pipe cutter, users should check to make sure that the cutting capacity is suitable for the PVC pipe size and schedule they expect to use.

Blade Material and Replaceability

The blade is one of the most important parts of a pipe cutter because it is responsible for slicing through the PVC. Depending on the type of pipe cutter, the blade can be a circular cutter wheel, a flat cutting edge, or a serrated cutting edge. Choose the type of cutter that is suitable for the project, and research the blade material. Look for products with heat-treated steel blades that are resistant to rust and corrosion.Another factor to pay attention to is the replaceability of the blade. Most PVC pipe cutters have replaceable blades, though the cost of the replacement blade might be higher than a new PVC cutter, so take the time to factor in the price of replacement blades before investing in a PVC pipe-cutting product.

Ergonomics

Whether using a manual cutter, spring-loaded cutter, or even an electric PVC pipe cutter, it’s important to consider the grip, ease of use, and any additional features that can improve the ergonomics of the tool. Padded handles with soft grips can increase the user’s comfort, making it easier to cut through PVC pipe without straining one’s hands.Consider looking for tools with helpful features, such as catch rings to hold the blade closed on a set of spring-loaded cutters or a textured adjustment knob on a set of manual pipe cutters that makes it easier to grip and adjust the cutting-wheel position. However, ratcheting and electric pipe cutters are the best choices for ease of use and comfort because these tools are designed to do most of the work.

Limit the strain and fatigue of cutting through durable PVC pipe by taking advantage of the ratcheting mechanism offered on these ratcheting pipe cutters. The cutting blade is made of sharpened manganese steel, while the body of the tool is lightweight die-casted aluminum. It also features curved handles that make it easier for the user to grip and control the alignment or positioning of the tool.

Use the PVC pipe cutters on chlorinated polyvinyl chloride (CPVC); PVC; acrylonitrile-butadiene-styrene (ABS); cross-linked polyethylene, or PEX, vinyl; or rubber tubing, and when the job is done, use the locking clip to keep the blade closed to prevent accidental injury or damage to the blade. However, it should be noted that the cutting capacity is suitable only for pipes with an outer diameter up to 1½ inches.

How We Chose the Best PVC Pipe Cutters

Due to the wide variety of pipe cutters, including manual, ratcheting, spring-loaded, electric, and even handsaws, it was necessary to research a broad pool of options to find suitable PVC pipe cutters for this list. The initial consideration during selection was based on the type of PVC pipe cutter as well as the overall quality of the products.With a range of pipe-cutting tools available, the next factor to help narrow down the potential products was the cutting capacity. PVC pipes can range in diameter, so it was important to have products capable of cutting through both small- and large-diameter PVC pipe. Durable products with blades that boasted substantial resistances to rust and corrosion were preferred over PVC pipe cutters that were more susceptible to water damage. The blade replaceability and ease of use also factored into the final decision for this list of the best PVC pipecutters.