Bi-Metal Hacksaw Blades

Premium quality bi-metal-hacksaw blades.

| Item No.: | CS048111 |

| Material | Bi-Metal Construction, M2 High Speed Steel Cutting Edge, D6A Steel Backing |

| Material of Handles: | ABS Plastic |

| Size: | 12"x1/2"x1/40" | 300mmx12.7mmx0.62mm |

| Teeth Per Inch (TPI) | 18 TPI, 24 TPI, 32 TPI |

| Surface Finshing: | Spray Painted |

| Application: | Suitable for Steel Tube, Copper Tube, PVC Tube, Metal Sheet |

| Packing: | 10pcs/bunch,100pcs/plastic box,1000pcs/ctn |

Detailed Description:

Chinese professional manufacturer of bi-metal hacksaw blades

Hacksaw Blade Selection Chart

| Material | Over 5mm | 2~5mm | Blow 2mm |

| Aluminium | 18 TPI | 18~24 TPI | 24~32 TPI |

| Asbestos | 18 TPI | 18~24 TPI | 24~32 TPI |

| Bronze | 18 TPI | 24~32 TPI | 32 TPI |

| Hard Rubber | 18 TPI | 18 TPI | 24 TPI |

| Copper | 18 TPI | 18~24 TPI | 24~32 TPI |

| Brass | 18 TPI | 24~32 TPI | 32 TPI |

| Hard Plastic | 18 TPI | 18~24 TPI | 24~32 TPI |

| Cast Iron | 18 TPI | 18~24 TPI | 24~32 TPI |

| Mild Steel | 18 TPI | 24 TPI | 32 TPI |

| Structural Steel- Low Alloy | 18 TPI | 24 TPI | 32 TPI |

| Structural Steel- High Alloy | 24 TPI | 24 TPI | 32 TPI |

| Tool Steel- Low Alloy | 18 TPI | 24 TPI | 32 TPI |

| Tool Steel- High Alloy | 24 TPI | 24 TPI | 32 TPI |

| High-Speed Steel | 24 TPI | 24 TPI | 32 TPI |

| Stainless Steel | 18 TPI | 24 TPI | 32 TPI |

What is Bi-Metal Saw Blade?

Bi-metal blades are a modern solution to cutting hard metals including steel. These blades are produced for many different styles of saws, including hacksaws, band saws, reciprocating saws and more. These blades last up to 10 times as long as traditional milled saw blades.

Bi-metal blades are a modern solution to cutting hard metals including steel. These blades are produced for many different styles of saws, including hacksaws, band saws, reciprocating saws and more. These blades last up to 10 times as long as traditional milled saw blades.

Bi-Metal Saw Blade's History

Before bi-metal blades were invented, saw blades were cut wholly from steel. But for more than 35 years bi-metal blades have been in use in all functions of cutting metal.How Does Bi-Metal Saw Blade Work?

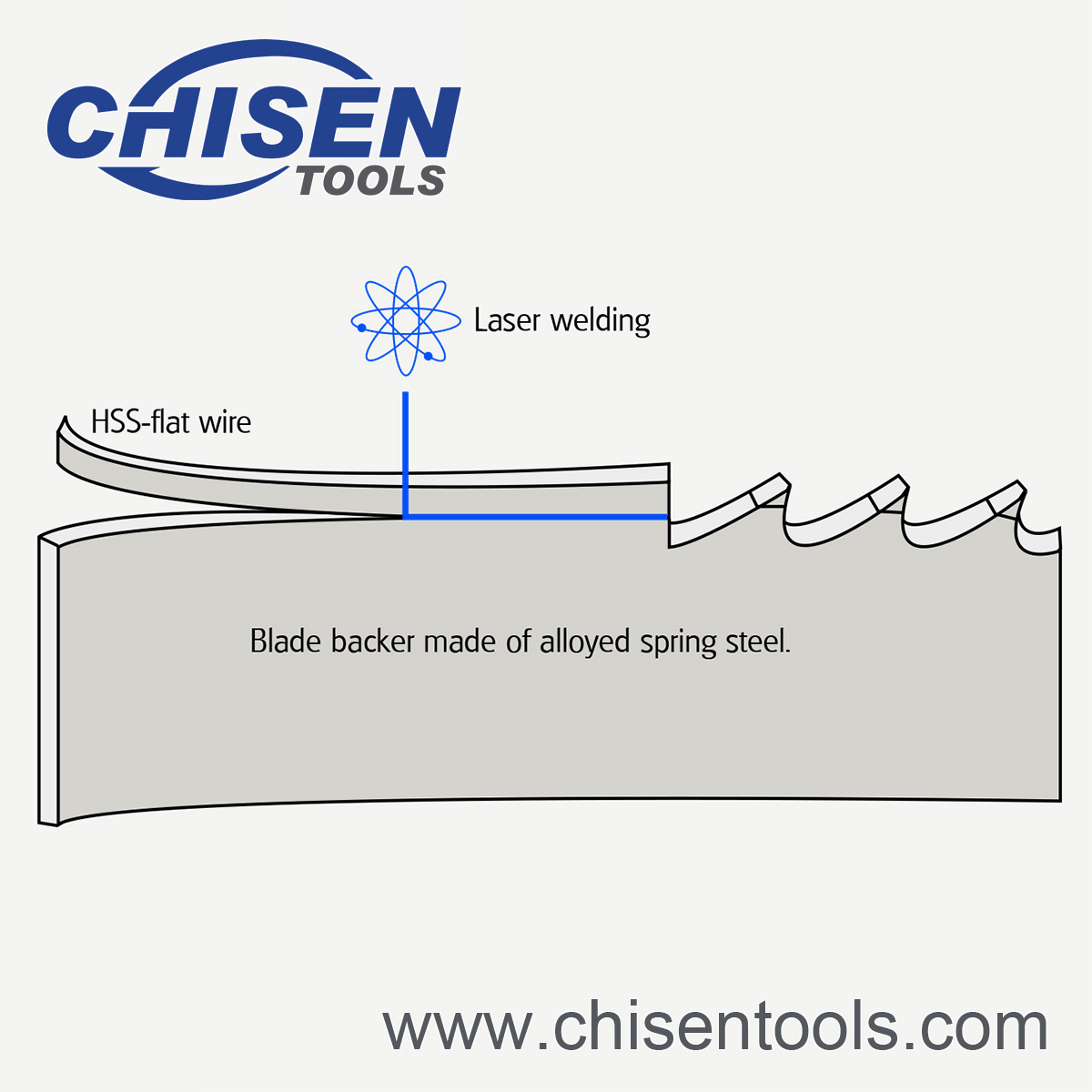

Bi-metal blades are, as their name suggests, made of two metals. These two metals, which are usually different types of steel are welded together. Spring steel is often used for backing and high-speed steel for edging.

Bi-metal blades are, as their name suggests, made of two metals. These two metals, which are usually different types of steel are welded together. Spring steel is often used for backing and high-speed steel for edging.