Hacksaw

Premium quality hacksaw.

| Item No.: | CS048011 |

| Material of Frame: | Square lacquered steel |

| Material of Handles: | ABS Plastic |

| Size: | 12" | 300mm |

| Surface Treatment: | Power Coated |

| Optional Hacksaw Blades: | Carbon Steel Blades, Bi-Metal Blades, High Speed Steel Blade |

| Application: | Suitable for Steel Tube, Copper Tube, PVC Tube, Metal Sheet |

Detailed Description:

Chinese professional manufacturer of hacksaw, hand hacksaw, hacksaw frame

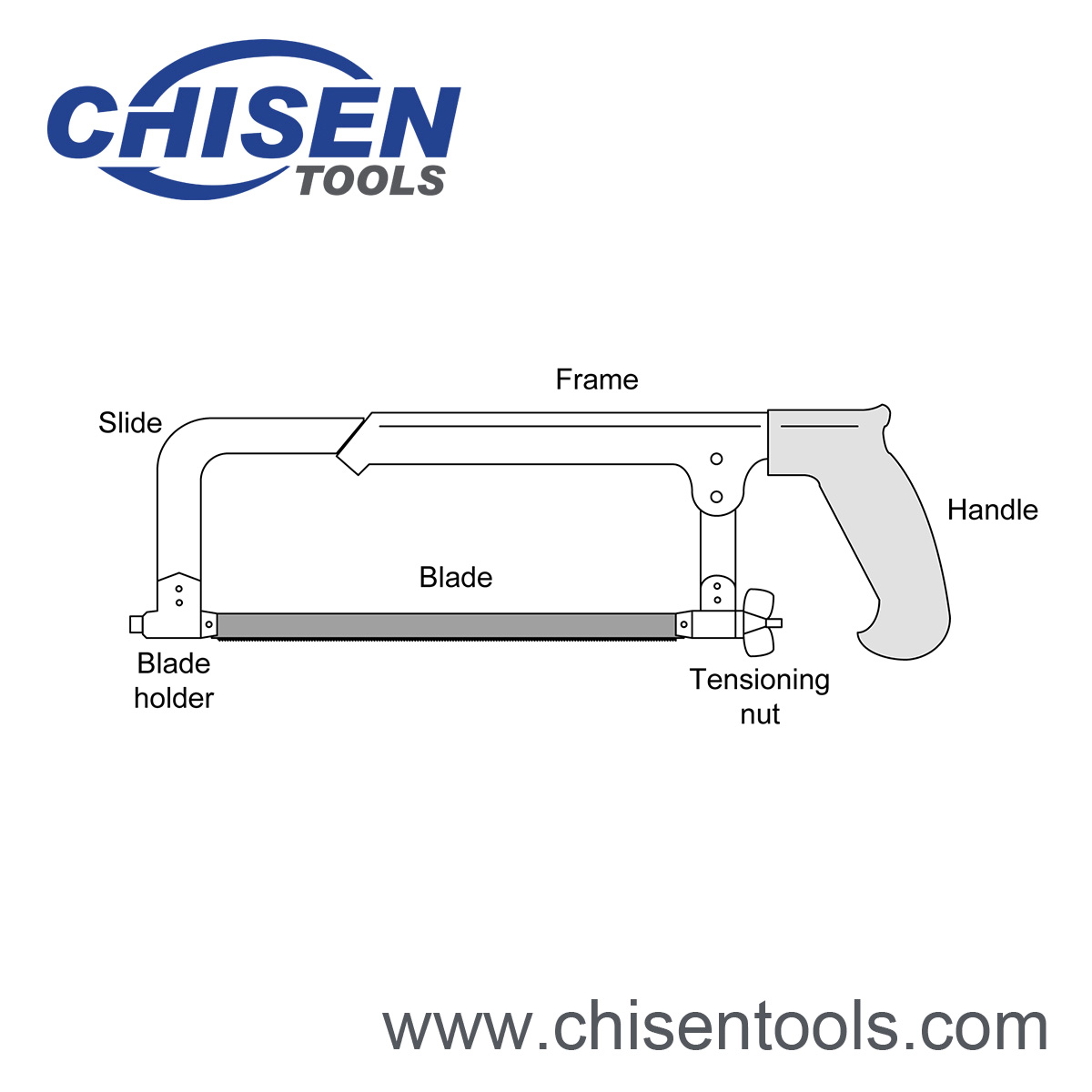

What is Hacksaw?

A hacksaw is a cutting tool with cutting-edge versatility. It is primarily used for cutting metal, and wood but it is versatile enough to cut through plastic and other materials. It comprises of metal frame that holds a thin and fine-toothed blade under tension and a handle. The hacksaw handle can be of different types including plastic, wooden, steel, or tubular metal handle. One can select a hacksaw of the desired handle based on their comfort or task requirement. Whether you are a professional or just a DIY enthusiast, the hacksaw is one of the most important tools that you’ll need again and again in your project.Purpose And Uses Of Hacksaw

From cutting metal to plastic, a hacksaw can do it all. Its primary purpose is to cut materials that are hard to cut using standard saws. It has applications in various areas including metalworking, construction, and plumbing. The most common applications of hacksaws include:- Shaping and cutting metal or plastic material.

- Slice the wood into pieces.

- Trim metal rods.

- Cut pipes and tubes.

Types Of Hacksaw

There are different types of hacksaw for every task. Let’s explore the most common types of hacksaws to help you understand the difference between them.Adjustable Hacksaw

Adjustable hacksaw is versatile in nature. You can adjust the frame length to accommodate different blade sizes that range between 10-12 inches. This feature makes it efficient for cutting various materials of different breadth. This type of hacksaw is suitable for tasks that require flexibility in blade sizes and materials.Fixed Frame Hacksaw

Unlike adjustable hacksaw, fixed frame hacksaw does not have an adjustable frame thus it cannot be adjusted for different blade sizes. Although it is not versatile, it offers stability and durability making it suitable for heavy-duty cutting tasks where strength and rigidity are required. These are used in cutting thick metal and other hard materials.Junior Hacksaw

As the name suggests, the junior hacksaw is a compact and lightweight version of a standard hacksaw. It contains a small blade that makes it suitable for tasks where you need to make precise cuts in confined spaces. Also, one can cut lightweight and thin materials such as plastic and metal sheets using a junior hacksaw. It is widely used ie fine and detailed cutting work.Power Hacksaw

Power hacksaws have heavier and wider frames and thicker blades than hand hacksaws. It is used in heavy-duty and large-scale cutting tasks in workshops and industries. It is powered with electricity or other power source to cut through materials. These are more efficient than the manually operated hacksaw as they maintain a consistent speed and depth of cut.Mini Hacksaw

The mini hacksaw is designed for small jobs that require precision and portability. It is lightweight and compact, thus it is easy to carry them around and use them in confined spaces. These are suitable for delicate and detailed cuts and cutting in confined spaces.Blade Types Of Hacksaws

The blades of the hacksaw come in different materials and teeth-per-inch (TPI) counts. Based on this, they can cut different types of material. Here are a few blade types used in the hacksaws:Carbon steel blades

Carbon steel blades are made with softer materials than other blade types. These are suitable for cutting soft materials such as copper, aluminum, and plastic. Carbon steel blades are light-duty and cost-effective making them ideal for general-purpose tasks. Such types of blades are not suitable for cutting thick and hard materials. Also, they are less durable than other blades, thus they have a short lifespan.High-speed steel blades

High-speed steel blades are more durable than carbon steel blades. These are designed to cut tough materials such as stainless steel, iron, and other hard metals. Such blades are heat resistant and can maintain their sharp edges when used under high-stress cutting conditions. However, these are less flexible than carbon steel blades, thus these are prone to snapping.Bi-metal blades

Bi-metal blades offer the toughness of high-speed steel and the flexibility of carbon steel. These blades are versatile and can cut through soft metals like plastic, as well as hard materials. Such a type of blade lasts longer as it is durable and resistant to wear and tear. Also, it is more expensive than carbon steel and HSS blades.Apart from the blade material, the number of teeth per inch (TPI) on the blade plays an important role in determining the cutting performance. The finer the teeth of the blade are, the smoother cut it will make.

Safety Tips For Using A Hacksaw

Although using a hacksaw is simple, its sharp blade raises safety concerns. Here are a few tips that one should consider while using a hacksaw:Hacksaw TPI

As seen in Figure 3, hacksaw blade teeth are forward facing and work like scoops to move material away from what is being cut. Typically, hacksaw teeth have 8, 14, 18, 24, or 32 TPI (tooth-per-inch).Lower TPI blades cut faster because they have larger teeth, which move more material away. However, these cuts are also coarser. High TPI blades are suitable for cleaner cuts because the small teeth slowly move material away. The following details some common applications for the range of TPI.

| Teeth Per Inch (25mm) | Suitable For Cutting |

| 14 TPI | Large Sizes, Aluminium and Other Soft Materials |

| 18 TPI | Suitable for General Workshop Cutting |

| 24 TPI | For Cutting Sheet Plate Up to 6mm |

| 32 TPI | For Cutting Hollow Sectionsand Tubing. |

Hacksaw Blade Selection Chart

| Material | Over 5mm | 2~5mm | Blow 2mm |

| Aluminium | 18 TPI | 18~24 TPI | 24~32 TPI |

| Asbestos | 18 TPI | 18~24 TPI | 24~32 TPI |

| Bronze | 18 TPI | 24~32 TPI | 32 TPI |

| Hard Rubber | 18 TPI | 18 TPI | 24 TPI |

| Copper | 18 TPI | 18~24 TPI | 24~32 TPI |

| Brass | 18 TPI | 24~32 TPI | 32 TPI |

| Hard Plastic | 18 TPI | 18~24 TPI | 24~32 TPI |

| Cast Iron | 18 TPI | 18~24 TPI | 24~32 TPI |

| Mild Steel | 18 TPI | 24 TPI | 32 TPI |

| Structural Steel- Low Alloy | 18 TPI | 24 TPI | 32 TPI |

| Structural Steel- High Alloy | 24 TPI | 24 TPI | 32 TPI |

| Tool Steel- Low Alloy | 18 TPI | 24 TPI | 32 TPI |

| Tool Steel- High Alloy | 24 TPI | 24 TPI | 32 TPI |

| High-Speed Steel | 24 TPI | 24 TPI | 32 TPI |

| Stainless Steel | 18 TPI | 24 TPI | 32 TPI |