Chinese professional manufacturer of sabre saw blades

Our company produce and supply a variety of HCS (High Carbon Steel) sabre saw blades and Bi-Metal sabre saw blades.

Sabre Saw Blade's Universal Shank

Fits:

Fits: AEG®, BLACK & DECKER®, BOSCH®, DEWALT®, FEIN®, FLEX®, HILTI®, MAKITA®, METABO®, MILWAUKEE®, PORTER CABLE®, RIDGID®, ROTHENBERGER®, RYOBI®, SKIL®.

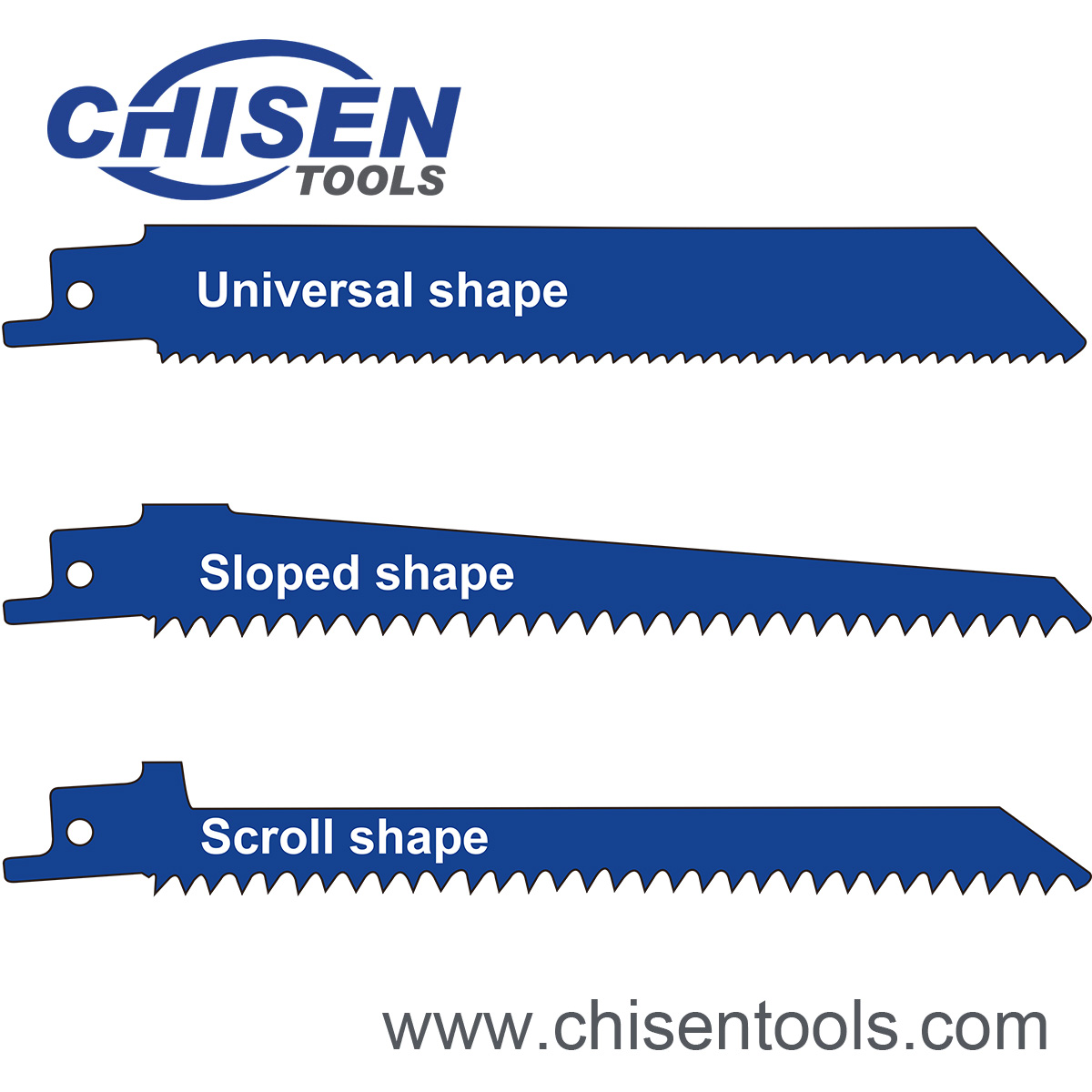

Three Main Sabre Saw Blade Sharps

Sabre Saw Blades vary in shape and thickness. These two characteristics are adjusted according to the demands of the application as well as the required flexibility. Rigorous applications such as cutting tube and pipe require thick robust blades, while less demanding applications require narrower blades.

Universal blades

Universal blades are for general use. Their even width guarantees good cutting stability and excellent control. This enables straight edge cutting through many different materials.

Sloped shape

Sloped blades are commonly used for cutting wood and for demolition applications. Their narrow tip allows for plunge and curve cutting. This shape is rarely used for metal, since the tip does not have the strength required for this application.

Scroll shape

Scroll blades are especially used for curve cutting. The narrower the blade, the smaller the radius it can cut.

HCS sabre saw blades

HCS (High Carbon Steel) sabre saw blades are specially adapted for wood working terms of hardness and resistance. They are also highly suitable for other relatively soft materials.

HCS sabre saw blades 3 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048201 |

HCS (High Carbon Steel) |

3 TPI |

8.5mm |

150x19x1.25mm |

Ground coarse wood, free of nails (<100mm), pruning green wood (diameter <100mm), especially for curve cuts/plunge cuts |

| CS048202 |

HCS (High Carbon Steel) |

3 TPI |

8.5mm |

225x19x1.25mm |

Ground coarse wood, free of nails (<175mm), pruning green wood (diameter <250mm) |

| CS048203 |

HCS (High Carbon Steel) |

3 TPI |

8.5mm |

300x19x1.25mm |

Ground coarse wood, free of nails (<250mm), frewood (diameter <175mm) |

HCS sabre saw blades 5 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048211 |

HCS (High Carbon Steel) |

5 TPI |

5.0mm |

240x19x1.5mm |

Ground coarse wood, free of nails (<190mm), pruning green wood (diameter <190mm), frewood (diameter <190mm) |

HCS sabre saw blades 6 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048221 |

HCS (High Carbon Steel) |

6 TPI |

4.3mm |

150x19x1.25mm |

Ground contruction wood (<100mm), wooden wall (<100mm), boards: chipboard, MDF (6~60mm), plywood, plastic (<100mm), especially for plunge cuts |

| CS048222 |

HCS (High Carbon Steel) |

6 TPI |

4.0mm |

300x22x1.5mm |

Wood (6~250mm), boards, plywood, plastic (6~250mm) |

HCS sabre saw blades 6-10 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048231 |

HCS (High Carbon Steel) |

6-10 TPI |

2.4-4.0mm |

200x19x1.25mm |

Contruction timber (6-150mm). Boards: chip, MDF (6-60mm) plywood, plastic (6-150mm), wooden panels (<175mm) |

Bi-Metal Sabre Saw Blades, Reciprocating Saw Blades

Designed for extensive metal applications

Ideal for making quick cuts through a range of metal types and gauges.

Reliably aggressive cutting

High-speed steel cutting edge and spring steel blacking helps strengthen the blade, reduce breaks, and provides durability for long blade life.

Cut through wood with nails with ease

Blade thickness and profile are ideal for cutting through dense wood with nails.

Bi-Metal

M42 Bi-metallic matrerial contains Cobalt at eight percent, specially suitable for cutting the hardly cutted materials. The bi-metallic blade is a combo with the blade made of high-speed steel, and with the main body made of spring steel, that is of great rigid and flexible, break-resistant and durable, long life for cutting both wood and metal materials with rapidness and uniformaty.

Bi-metal sabre saw blades 24 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048251 |

Bi-Metal |

24 TPI |

1.0mm |

150x19x0.9mm |

Thin sheet metal (0.7~3mm), fine pipes/profiles (diameter 5~100mm). Effortless, fine cutting. |

| CS048252 |

Bi-Metal |

24 TPI |

1.0mm |

225x19x0.9mm |

Thin sheet metal (0.7~3mm), fine pipes/profiles (diameter 5~175mm). Effortless, fine cutting, flexible flush cut. |

Bi-metal sabre saw blades 14 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048261 |

Bi-Metal |

14 TPI |

1.8mm |

150x19x0.9mm |

Thin sheet metal (3~8mm), solid pipes/profiles (diameter <100mm). Quick cut. |

| CS048262 |

Bi-Metal |

14 TPI |

1.8mm |

225x19x0.9mm |

Thin sheet metal (3~8mm), solid pipes/profiles (diameter <175mm). Quick cut, flexible flush cut. |

Bi-metal sabre saw blades 18 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048271 |

Bi-Metal |

18 TPI |

1.4mm |

150x19x0.9mm |

Thin sheet metal (1.5~4mm), pipes/profiles (diameter <100mm). |

| CS048272 |

Bi-Metal |

18 TPI |

1.4mm |

225x19x0.9mm |

Thin sheet metal (1.5~4mm), pipes/profiles (diameter <175mm). Flexible flush cut. |

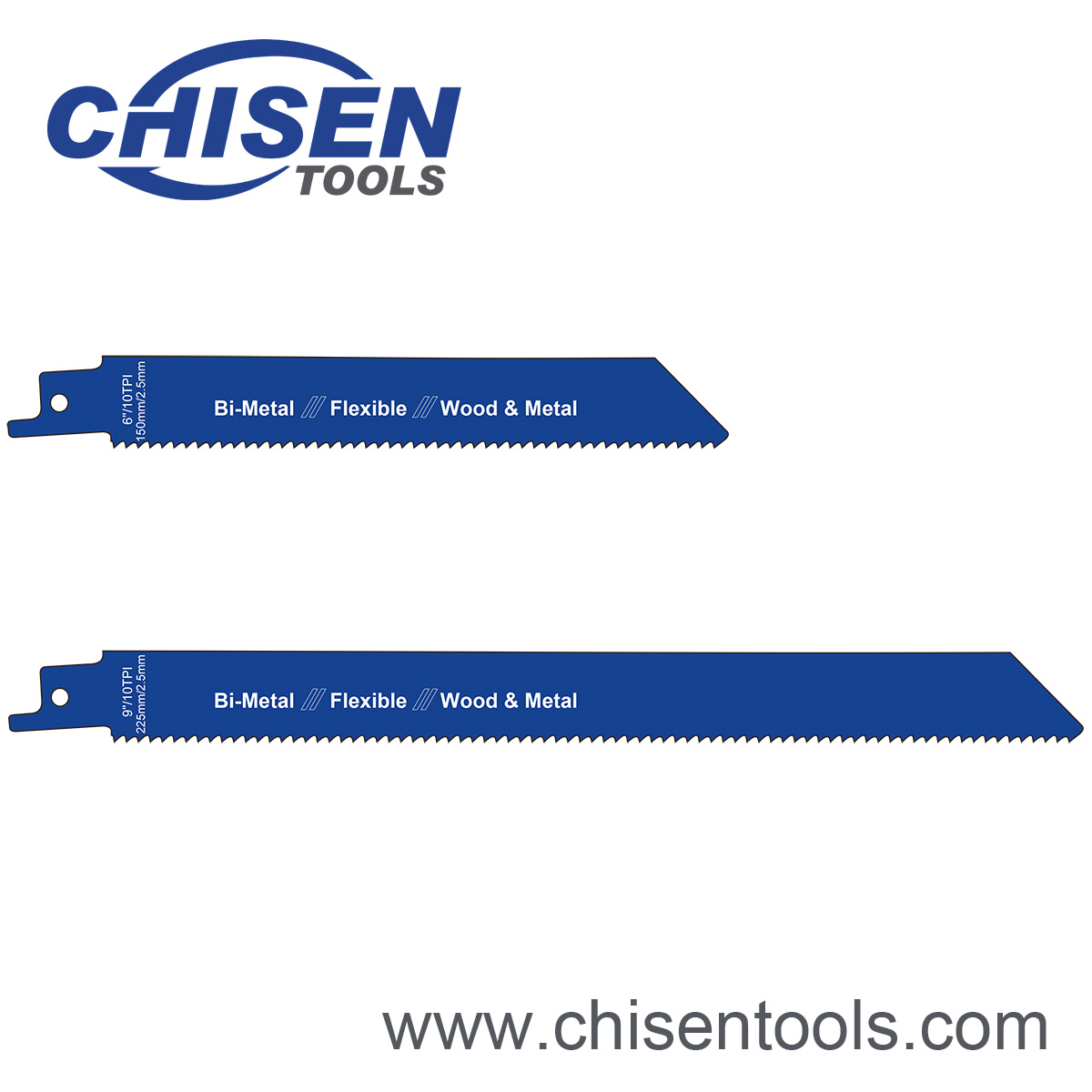

Bi-metal sabre saw blades 10 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048281 |

Bi-Metal |

10 TPI |

2.5mm |

150x19x0.9mm |

For pallet repair, wood with nails/metal (5~100mm), sheet metals, pipes, aluminium profiles (3~12mm) |

| CS048282 |

Bi-Metal |

10 TPI |

2.5mm |

225x19x0.9mm |

For pallet repair, wood with nails/metal (5~175mm), sheet metals, pipes, aluminium profiles (3~12mm). Flexible flush cutting. |

Bi-metal sabre saw blades 10-14 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048291 |

Bi-Metal |

10-14 TPI |

1.8-2.6mm |

150x19x0.9mm |

Vario-pithed teeth. Wood with nails/metal (5~100mm), sheet metal, piples, alumiunium profiles (3~10mm), plastic profiles (diametal 3~100mm). |

| CS048292 |

Bi-Metal |

10-14 TPI |

1.8-2.6mm |

225x19x0.9mm |

Vario-pithed teeth. Wood with nails/metal (5~175mm), sheet metal, piples, alumiunium profiles (3~10mm), plastic profiles (diametal 3~175mm). Flexible flush cut. |

| CS048293 |

Bi-Metal |

10-14 TPI |

1.8-2.6mm |

300x19x0.9mm |

Wood with nails/metal (5~250mm), sheet metal, piples, alumiunium profiles (3~10mm), plastic profiles (diametal 3~250mm). Flexible flush cut. |

Bi-metal sabre saw blades 6 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048301 |

Bi-Metal |

6 TPI |

4.3mm |

150x19x1.25mm |

Wood with nails/metal, chipboards (10~100mm), plastic profiles (diametal 5~100mm), plastics/glass fiber reinforced plastic, solid (8~50mm), windows frames: wood + metal. Especially for plunge cut. |

| CS048302 |

Bi-Metal |

6 TPI |

4.3mm |

150x19x1.25mm |

Wood with nails/metal, chipboards (10~100mm), plastic profiles (diametal 5~100mm), plastics/glass fiber reinforced plastic, solid (8~50mm) Especially for curve cut. |

| CS048303 |

Bi-Metal |

6 TPI |

4.3mm |

225x19x1.25mm |

Wood with nails/metal, chipboards (10~100mm), plastic profiles (diametal 5~175mm), plastics/glass fiber reinforced plastic, profiles (5~60mm). |

| CS048305 |

Bi-Metal |

6 TPI |

4.3mm |

300x19x1.25mm |

Wood with nails/metal, chipboards (10~250mm), aerated concrete (10~250mm), plastics/glass fiber reinforced plastic, profiles (5~60mm). |

Bi-metal sabre saw blades 6-12 TPI

| Item No. |

Material |

Teeth per Inch |

Teeth Pitch |

Size |

Application |

| CS048301 |

Bi-Metal |

6-12 TPI |

2.1-4.3mm |

200x19x1.25mm |

Wood with nails/metal, chipboards (<150mm), sheet metals, aluminium profiles (3~18mm), glass fiber, reinforced plastic/epoxy (<150mm). |

Hacksaw Blade Selection Chart

| Material |

Over 5mm |

2~5mm |

Blow 2mm |

| Aluminium |

18 TPI |

18~24 TPI |

24~32 TPI |

| Asbestos |

18 TPI |

18~24 TPI |

24~32 TPI |

| Bronze |

18 TPI |

24~32 TPI |

32 TPI |

| Hard Rubber |

18 TPI |

18 TPI |

24 TPI |

| Copper |

18 TPI |

18~24 TPI |

24~32 TPI |

| Brass |

18 TPI |

24~32 TPI |

32 TPI |

| Hard Plastic |

18 TPI |

18~24 TPI |

24~32 TPI |

| Cast Iron |

18 TPI |

18~24 TPI |

24~32 TPI |

| Mild Steel |

18 TPI |

24 TPI |

32 TPI |

| Structural Steel- Low Alloy |

18 TPI |

24 TPI |

32 TPI |

| Structural Steel- High Alloy |

24 TPI |

24 TPI |

32 TPI |

| Tool Steel- Low Alloy |

18 TPI |

24 TPI |

32 TPI |

| Tool Steel- High Alloy |

24 TPI |

24 TPI |

32 TPI |

| High-Speed Steel |

24 TPI |

24 TPI |

32 TPI |

| Stainless Steel |

18 TPI |

24 TPI |

32 TPI |

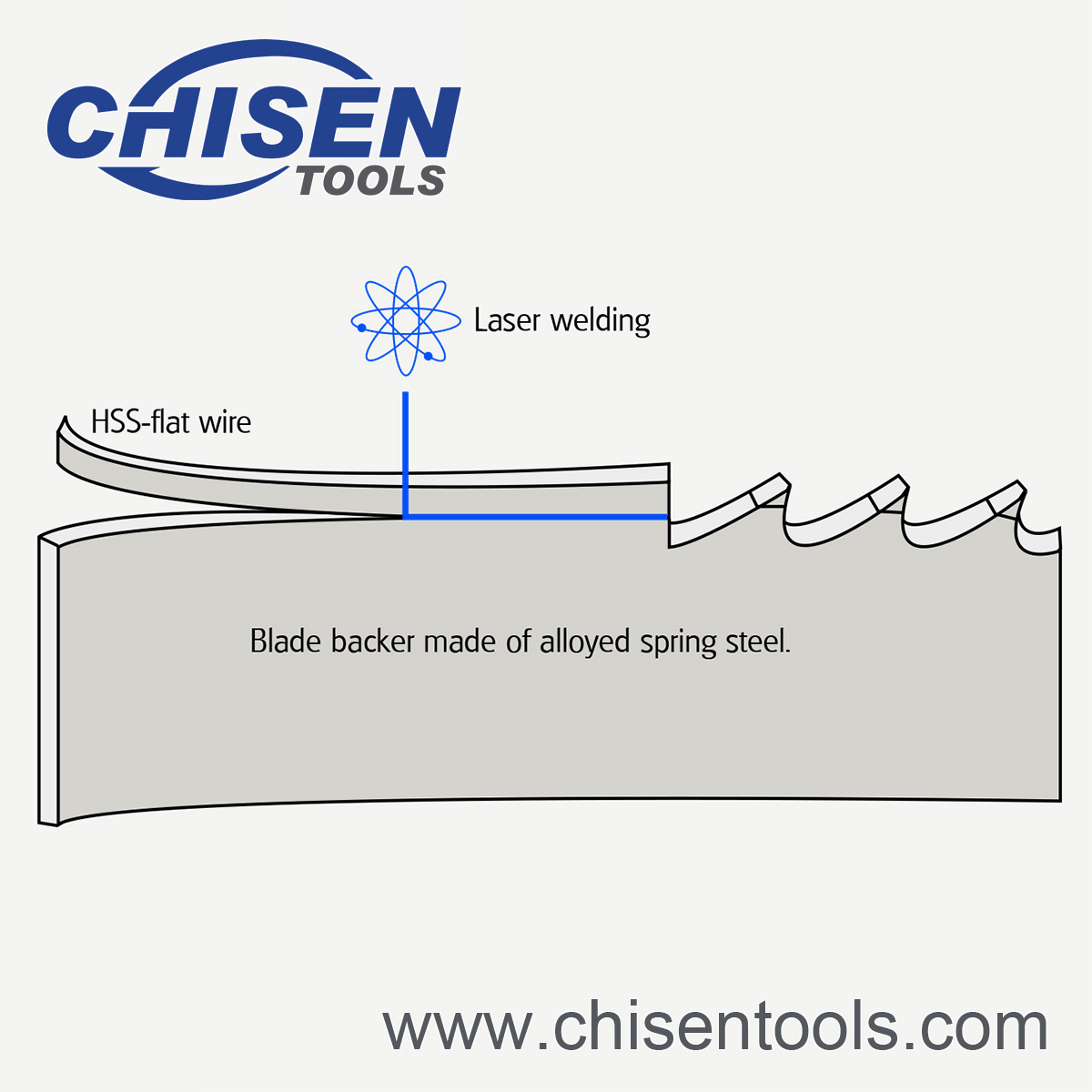

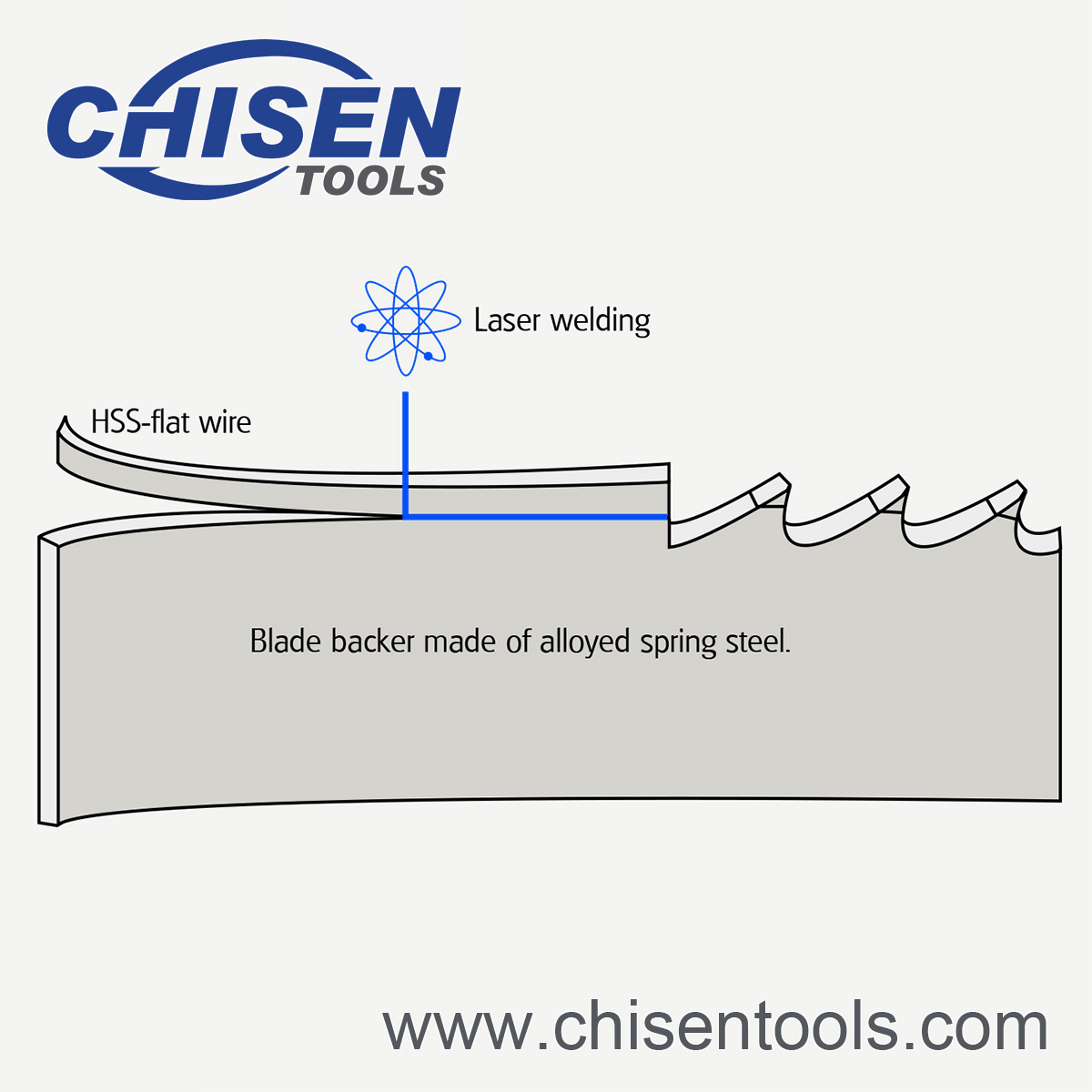

What is Bi-Metal Saw Blade?

Bi-metal blades are a modern solution to cutting hard metals including steel. These blades are produced for many different styles of saws, including hacksaws, band saws, reciprocating saws and more. These blades last up to 10 times as long as traditional milled saw blades.

Bi-Metal Saw Blade's History

Before bi-metal blades were invented, saw blades were cut wholly from steel. But for more than 35 years bi-metal blades have been in use in all functions of cutting metal.

How Does Bi-Metal Saw Blade Work?

Bi-metal blades are, as their name suggests, made of two metals. These two metals, which are usually different types of steel are welded together. Spring steel is often used for backing and high-speed steel for edging.

Bi-Metal Saw Blade's Benefits

Because of the welding process, which is usually done with an electron beam, weld teeth last longer and are able to cut through harder materials, such as steel, more easily.

Bi-Metal Saw Blade's Uses

While bi-metal blades can be used for many different materials, the most commonly used bi-metal blades are designed to cut different forms of metals. The determining factor is the teeth per inch; more teeth per inch (tpi) are used to cut harder materials.

Bi-Metal Saw Blade's New Improvements

Additions of new metals, such as chromium, and new bonding techniques, such as diffusion bonding, are adding strength and helping reduce heat. Heat especially is a damaging factor in blades and can break teeth off.

Our company produce and supply a variety of HCS (High Carbon Steel) sabre saw blades and Bi-Metal sabre saw blades.

Our company produce and supply a variety of HCS (High Carbon Steel) sabre saw blades and Bi-Metal sabre saw blades.

Fits: AEG®, BLACK & DECKER®, BOSCH®, DEWALT®, FEIN®, FLEX®, HILTI®, MAKITA®, METABO®, MILWAUKEE®, PORTER CABLE®, RIDGID®, ROTHENBERGER®, RYOBI®, SKIL®.

Fits: AEG®, BLACK & DECKER®, BOSCH®, DEWALT®, FEIN®, FLEX®, HILTI®, MAKITA®, METABO®, MILWAUKEE®, PORTER CABLE®, RIDGID®, ROTHENBERGER®, RYOBI®, SKIL®.

Bi-metal blades are a modern solution to cutting hard metals including steel. These blades are produced for many different styles of saws, including hacksaws, band saws, reciprocating saws and more. These blades last up to 10 times as long as traditional milled saw blades.

Bi-metal blades are a modern solution to cutting hard metals including steel. These blades are produced for many different styles of saws, including hacksaws, band saws, reciprocating saws and more. These blades last up to 10 times as long as traditional milled saw blades.

Bi-metal blades are, as their name suggests, made of two metals. These two metals, which are usually different types of steel are welded together. Spring steel is often used for backing and high-speed steel for edging.

Bi-metal blades are, as their name suggests, made of two metals. These two metals, which are usually different types of steel are welded together. Spring steel is often used for backing and high-speed steel for edging.